Hydraulic Flow Control Solutions

The Hidden Power of Precision Engineering

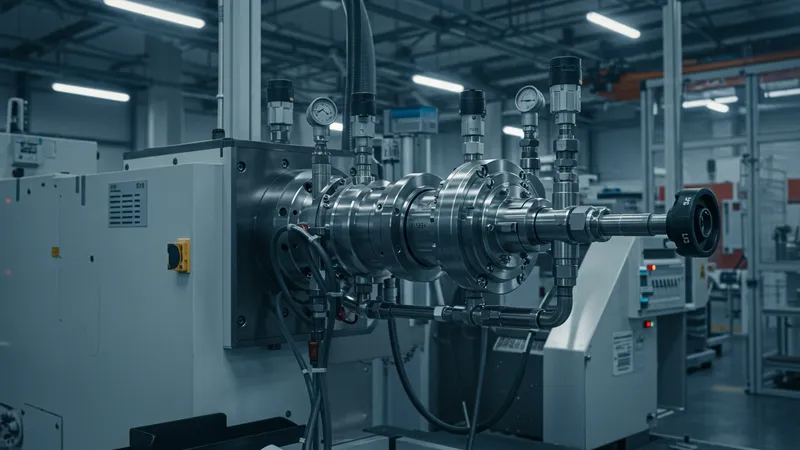

The intricate dance of hydraulic flow control is more than just pressure and fluid dynamics. It’s about precision engineering that can scale to any application, from the smallest vehicle components to the most massive industrial machines. The precision in tools ensures that every ounce of pressure is accounted for, cutting down errors significantly. But there’s one more twist…

Unexpected advancements in sensor technology have allowed engineers to pinpoint inefficiencies with astonishing accuracy. By integrating intelligent sensors, companies are not only saving energy but also prolonging the lifespan of their machinery. This integration of smart technology might seem futuristic, but it’s already here, unfolding quietly across industries.

This capability to monitor and fine-tune hydraulic systems in real-time is revolutionizing how industries envision maintenance. Forget about unexpected downtimes; the age of predictive maintenance is upon us. And it just might save millions for companies every year. What you read next might change how you see this forever.

However, the real innovation lies in the symbiosis between human expertise and machine efficiency. This partnership is crafting new pathways to innovation that were once thought impossible. There’s still more to uncover about the critical role humans play in this high-tech landscape…