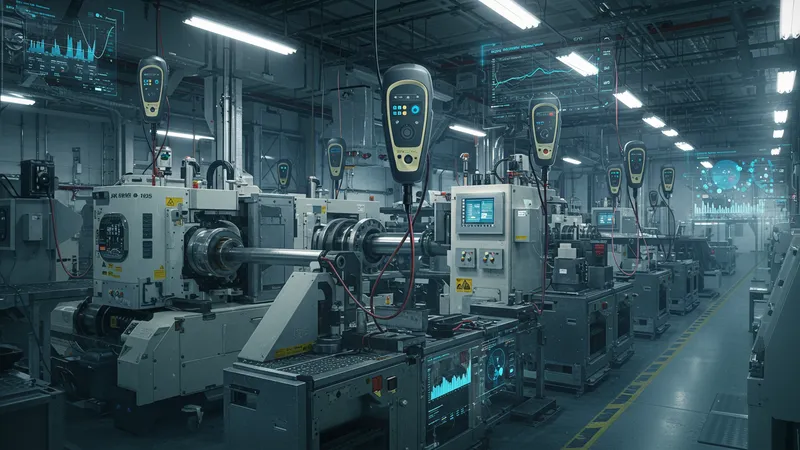

Proximity Probe Monitoring Solutions: Enhancing Precision And Reliability In Industrial Machinery

Imagine your industrial equipment whispering its status, predicting downtimes with precision, and optimizing performance seamlessly. Proximity probe monitoring solutions aren’t just a futuristic dream—they are here, reshaping maintenance strategies.

In today’s fast-paced industrial landscape, where even a minor disruption can result in staggering losses, investing in precision tools equipped with proximity probes is critical. But few realize just how game-changing these solutions can be.

- Used by leading manufacturers, Bentley Nevada offers reliability with robust sensors starting at $500 per unit.

- The revolutionary Schneider Electric systems optimize workflows, with full setups beginning at $1,200.

Proximity probe technology goes beyond mere detection; it minimizes downtime, enhancing machinery life spans. These systems are transforming industries by offering superlative accuracy and signalling wear before a fault occurs. Imagine a conveyor shutdown saved by early alerts. But that’s not even the wildest part…

Prominent businesses report a 30% increase in machine reliability, sparking a quiet revolution in machinery maintenance. Advanced analytics combined with wireless capability means conditions are monitored round the clock. But here’s an unexpected aspect: deployment is faster and less costly than traditional methods, making it accessible to smaller enterprises as well. But that’s not even the wildest part…

What’s next shocked even the experts: the next evolution of proximity probe technology promises a leap in predictive precision. Curious about this groundbreaking advancement? You won’t believe how it’s poised to redefine industries. Get ready to dive deeper into the unexpected, as we explore the intricacies of these solutions and the astonishing transformations they’re bringing about.