Proximity Probe Monitoring Solutions: Enhancing Precision And Reliability In Industrial Machinery

The Critical Role of Proximity Probes in Machine Health

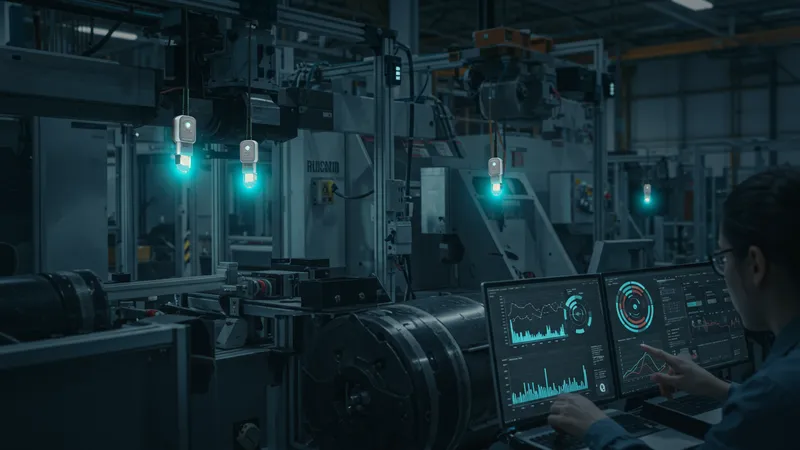

Every factory manager knows that machine breakdowns lead to unforeseen downtime, which translates into financial losses. Proximity probes stand at the forefront of the fight against unexpected failures by providing accurate monitoring of machinery movements. They detect changes you can’t see and warn you before things go awry.

These sensors have become the silent guardians of industrial health. With their ability to capture minute variations in positions or vibrations, proximity probes alert operators to potential failures. This allows for scheduled maintenance rather than reactionary fixes, preserving productivity and preventing costly halts in production lines.

Unlike traditional methods, proximity probes offer refined insights with real-time data. This empowers decision-makers with substantial information to optimize operational efficiency and prolong machine longevity. Being proactive rather than reactive changes the game entirely for industries on tight margins.

But there’s one more twist: recent developments in AI-driven analytics integrated with these sensors are pushing the boundaries of what’s possible. What you read next might change how you see this forever—stay tuned as we delve into how AI enhancements are revolutionizing proximity probe technologies.