The Evolution And Impact Of Industrial Machines: Driving Modern Manufacturing

Technological Advancements Leading the Charge

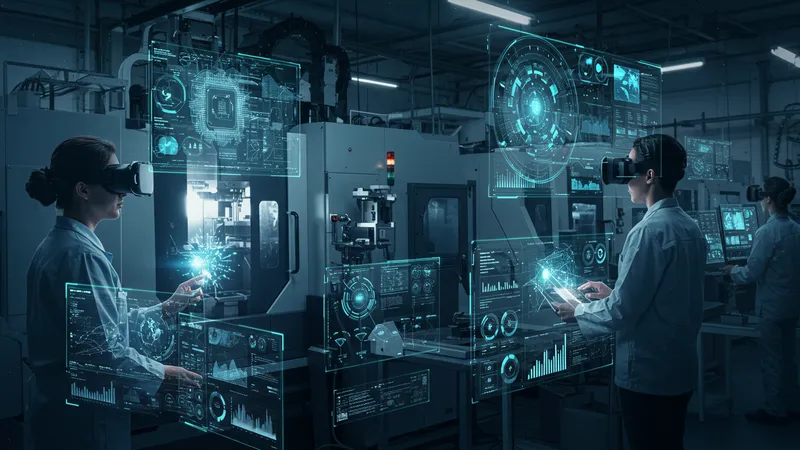

Behind the industrial machines’ transformation lies a relentless march of technological advancements. From AI-driven predictive maintenance to digital twins—a virtual replica of physical machines—these technologies redefine modern manufacturing. Digital twins, for instance, allow for real-time monitoring and testing of machinery, preventing costly errors and enabling proactive management. Adoption of such revolutionary tech is soaring, yet it unveils challenges in data management and system integration. But what does this mean for the industry’s future?

Embracing these innovations requires not just investment, but a cultural shift within companies. Rapid tech adoption changes workflows and necessitates upskilling and retraining the workforce. Employees need to move beyond basic operational skills to master software interfaces and data analysis. Companies leading these transformations experience a significant competitive edge, yet the journey is fraught with teething issues. What remains untapped is the potential for cross-industry collaborations to streamline tech integration and maximize value.

Amidst the digital transformation, cybersecurity emerges as a formidable challenge. As machines become more interconnected, the risk of cyber threats targeting industrial systems grows. Incidents of deliberate disruptions and system hijackings highlight vulnerabilities that many companies are still ill-prepared to tackle. Investing in robust cybersecurity protocols and fostering an organizational culture of vigilance becomes non-negotiable. Could it be that, without these measures, the industry could fall victim to its own technology?

The next step? Developing smart factories fully integrated with Internet of Things (IoT) devices, providing seamless communication and operational efficiency. These smart ecosystems promise unprecedented responsiveness and flexibility in manufacturing, but they also demand significant upfront investments and careful planning. The long-term vision of a fully interconnected industrial landscape could redefine manufacturing but not without significant reshaping of the current infrastructures. What you read next might change how you see this forever.