Unveiling The Power And Precision Exploring Industrial Machines

Industrial Machines: Power Scaling and Performance Comparison

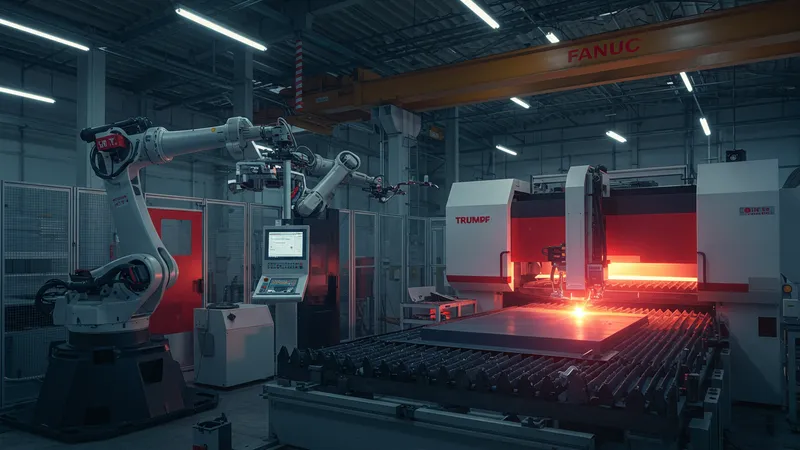

The range of power output among leading industrial machines shows the versatility of today’s machinery. FANUC robots are recognized for their ability to handle payloads ranging from just a few kilograms up to massive components. Their design allows for a rapid speed of operation, sometimes exceeding 2,000 millimeters per second. This strength, combined with precise articulation, supports both large-scale and highly detailed work without requiring tool changeovers or manual adjustment.

TRUMPF’s laser cutting equipment leverages advanced fiber laser sources capable of generating up to 12,000 watts of focused energy. This immense capability allows users to cut through thick sheets of steel quickly and consistently. Yet, the fine adjustment features—such as automated nozzle exchange and real-time feedback—ensure edges are smooth and measurements are exact, regardless of material hardness or complexity.

For Mazak’s CNC machining centers, performance is measured in both speed and repeatability. Spindle speeds can surpass 15,000 RPM, with automated tool changers enabling continuous operation. A critical factor is thermal stability—sensors monitor temperature to compensate for expansion or contraction, guaranteeing the final product’s dimensions remain exact throughout long production runs. Such performance is key for high-value sectors needing reliable, precision-focused outcomes.

Comparing these machines, it’s clear that engineers and decision-makers must carefully assess use case requirements. Not every task needs the raw power of a TRUMPF laser, nor the minute repeatability of a high-end CNC mill. Understanding the balance between force, speed, and precision ensures that businesses maximize both productivity and quality, whether for one-off prototypes or mass-produced components.