Unveiling The Power And Precision Exploring Industrial Machines

Technological Innovation in Power and Precision

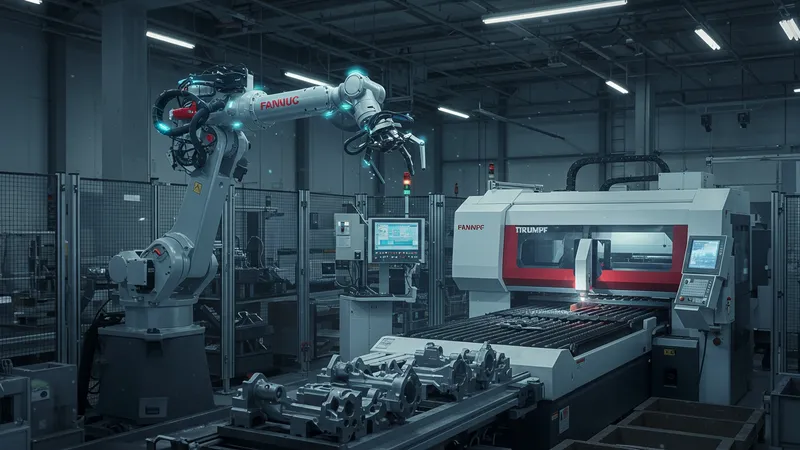

The marriage of digital technologies and mechanical engineering has radically transformed industrial machines’ capabilities. FANUC robots integrate artificial intelligence and vision recognition, allowing them to identify parts, adjust routines, and correct deviations without halting operations. This advancement reduces downtime, improves consistency, and minimizes errors—critical traits for manufacturers pursuing lean production processes or handling mixed product lines.

Laser cutting systems like those from TRUMPF benefit from real-time process monitoring. Sensors embedded in the cutting head measure factors such as temperature, beam focus, and surface reflections. This data is processed instantaneously to adjust energy output and motion, keeping tolerances within prescribed limits—even when dealing with varying material thicknesses or reflective surfaces. The result is fewer defects and greater material efficiency.

Mazak CNC machining centers have embraced complex software platforms and IoT connectivity. Operators can simulate machining cycles, analyze tool wear, and schedule preventive maintenance remotely. These “smart factories” optimize each phase of production, not only boosting throughput but ensuring that the most stringent standards of accuracy and surface finish are repeatedly met, even on challenging geometry or exotic materials.

These ongoing innovations don’t just increase output; they set new norms across manufacturing industries worldwide. With each generation, industrial machines become more autonomous, adaptable, and able to deliver scalable advantages—demonstrating that power and precision are no longer competing priorities but partners driving progress forward.