Unveiling The Power And Precision Exploring Industrial Machines

Benefits for Manufacturing and Industry Standards

The adoption of powerful, precise machinery has led to significant benefits for manufacturers and their customers. FANUC robots speed up production lines, leading to shorter lead times and greater flexibility when switching between products. This efficiency results in consistent product quality and enables companies to respond quickly to changing market demands, solidifying their competitive position.

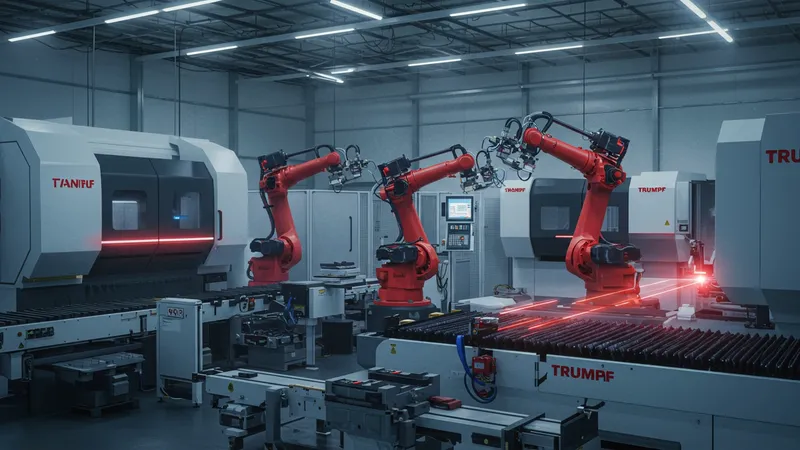

TRUMPF laser cutters are now integral in industries where flawless material processing is essential. Their exceptional edge quality reduces the need for secondary finishing and enhances the fit and function of parts in complex assemblies. For sectors like automotive and aerospace, this reliability ensures regulatory compliance and minimizes rework, lowering overall production costs without compromising quality.

Mazak CNC machining centers provide the foundation for producing high-precision components across medical device, energy, and electronics industries. Their ability to fabricate parts with minimal dimensional variance supports innovations in miniaturization and advanced engineering designs. This consistency helps maintain industry certifications and promotes trust among demanding clients who value predictability and repeatability in supplied components.

Wider adoption of advanced machines also raises the baseline for global industry standards. As organizations invest in higher-performing equipment, benchmarks shift upward, prompting regular reviews of tolerances, surface finishes, and testing protocols. This cycle propels innovation and prompts peer sectors to advance, ensuring sustained progress across the entire manufacturing landscape.